PUMP MIXERS

SARAKA Oy manufactures pump mixers in Finland in cooperation with reliable component suppliers. In addition, we deliver standard European pump mixers from the manufacturers we represent, either complete inclusive the chassis, or mounted on a customer-supplied truck chassis.

![]()

LSB LIGHT WEIGHT DRUMS FOR PUMP MIXERS

LSB6

LSB7

LSB8

LSB9

SARAKA LSB-B serie is designed to leave space for accessory like boom

ECONOMY AND BENEFITS

With the SARAKA pump mixer you are clearly transporting the best payload on the market on all 3, 4 or 5 axle chassis as you choose. The low kerb weight is based on the best special steel lightweight technology and weight optimized technical component solutions. Each cubic more payload generates significant additional revenue per year. SARAKA transport pumps are also customized to meet customer needs, making work easier and increasing productivity.

SARAKA pump mixers are highly valued on second hand market giving another benefit when it’s time for renewall of the fleet.

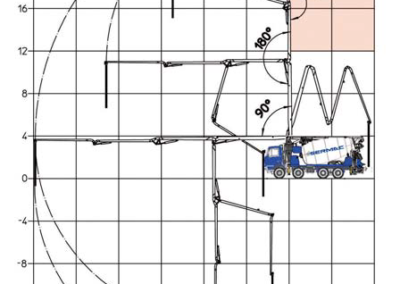

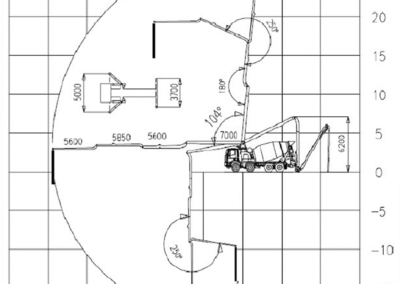

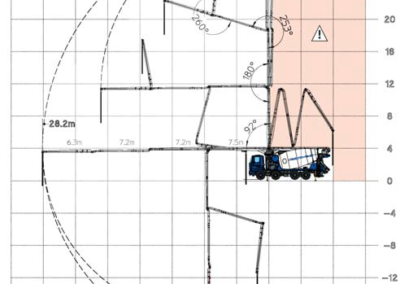

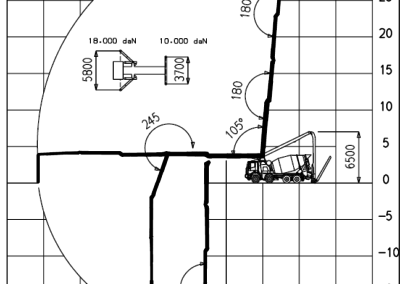

BOOMS FOR PUMP MIXERS

You can choose from models 4Z28, 4Z29, 4Z33 and 5Z35

Lightweight but durable construction is included in the manufacture of all pump mixer booms. The booms consist of three, four or five elements and all open with a fast Z-fold. The speed of the easy-to-use booms can be adjusted infinitely and with smooth soft movements. Proportional radio control can be implemented as the customer wishes with a piano or joystick type radio.

CORE PUMPS

PUMPING UNITS available are

– SC2070 D=200 mm

The installation of the pumping unit is aimed at a small rear overhang and a large ground clearance, however, so that the discharge height for the pump is as low as possible.

As a specialty, SARAKA also manufactures equipment with a removable pumping unit. Such an option is a tower integrated into a removable pump and thus a rear-mounted boom – SARAKA EKO – which can be installed as an accessory to almost any transport mixer. Thus, the existing transport truck will always be provided with an accessory to make it into a pump mixer, but at other times, without any accessory, the best possible payload will be used.

Another option is a fixed boom mounted behind the cabin, but a removable pumping unit – SARAKA CITY. More about these specialties in the ‘SPECIAL EQUIPMENT’ section

Fast service over network with adjustment or fault analysis significantly reduces downtime and keeps the device working. Better payload, easier and more productive work and less downtime – this will result in a very fast payback time for device purchases.

DESIGNED FOR SCANDINAVIAN HARSH CONDITIONS

SARAKA concrete pumps are already designed to function reliably in the cold and humid conditions of the North. One particular example of this is the SARAKA electrical and IQAN control system.

SERVICE OVER INTERNET

The SARAKA pump mixer can be connected over the Internet directly to the factory whenever a strong mobile network is available. The immediate analysis of the potential disruption by the factory’s best experts is thus readily at your disposal. Also, if you want to get the pump functions, speeds, or directions adjusted, the updates can most often be done easily over the Internet.

STRUCTURE MAKES THE DIFFERENCE

The design of the SARAKA mixers has taken into account the design of the pump mixer, which provides several advantages. The capacity of the narrow mixer can be optimized according to the dimensions of the chassis and the customer’s needs, and the space on the side of the tank is loosely spaced regardless of its size and design. The narrowly shaped mixer also lowers the center of gravity of the transported mass and prevents the lateral displacement of the load in the bends, greatly improving the driving characteristics. When manufacturing the device, we take into account the customer’s needs for special solutions and accessories to facilitate daily work and improve productivity.

SIMPLE USE

The control system for the SARAKA IQAN concrete pumps is designed to meet the needs of concrete pumping and the requirements for safe operation of the equipment on site. The control system implemented with the help of highly humidified (IP69) components provides the user with more information about the operation of the device and allows the operator to perform fine tuning. The control system can be connected to the mobile network by the user, which makes it possible to analyze the status of the device and, if necessary, update the programming directly from the factory.

DIVIDED POWERTRAIN

SARAKA has developed own technical solutions to gain savings in kerb weight and simultaneously ensure functional security. Hydraulic pumps are divided to engine PTO and to gearbox PTO of the vehicle.

Core pumps for SARAKA pump mixers can be picked from three different functional principles:

– fully hydraulic function by hydraulic pilot signals

– conventional electric pumping/suction with change over by hydraulic pilot signals

– reliable inductive sensors commanding all functions

BEST MIXING PROPERTIES

SARAKA has developed special auxiliary blades that ensure a smooth and even mixing of homogeneous concrete and on-site additives or fibers into the pulp.

Accessory

Self-return stainless hose reel with 10 m hose and washer nozzle

Parlok mudguard

A sealed tailgate for the mixer integrated into the loading hopper